|

|

|||||||

| Register | FAQ | Members List | Calendar | Gallery | Today's Posts | Mark Forums Read | Search |

| Loudspeakers Your DIY Speaker designs |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

I got a pair of these used a few months ago after reading very positive reviews from Noel at HFW and thinking they should work well in our room.

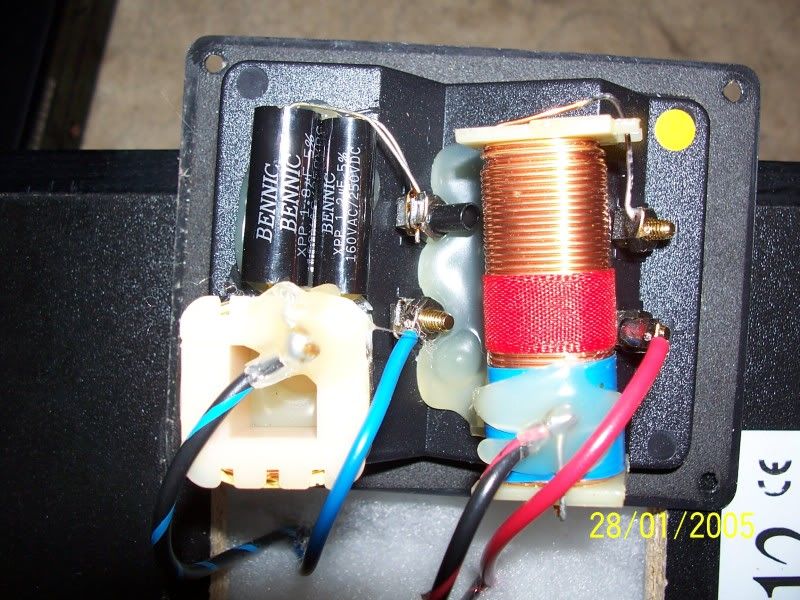

http://www.castle.uk.com/LinkClick.a...language=en-US I must say I agree completely with the review. A flawed gem of a speaker. I lived with it and it educated my ears to a different presentation. I still missed a little air and sparkle at the top end though. First job was to try the spikes. The mounting inserts were loose in the MDF plinths so I'd not used them yet. They wobbled and rotated but wouldn't pull out by hand. To stop the insert pulling the MDF to pieces around the hole I put a large washer on first, with a hole just large enough for the insert, then stacked more washers and used the spike nut and thread to draw the insert out with a spanner. Refitted them with epoxy and they work properly now. That tightened up and focussed the sound and was well worth the effort but Noel's measurements and my ears said I should look at the crossover. It came out easily, just up-ended the speaker, undid the 8 screws on the terminal panel, and there it is on the back. Very high quality parts for a commercial design. So are the drivers and cabs too. Followed the circuit and drew it out below. It's clear to see the 3R3 attenuating resistor for the tweeter on the left in the pic connected directly to one end of the 4.7uF. Did the maths and figured that for a nominal 8 ohms 3R3 gave -3dB to the tweeter. Changing that to 1R2 would give -1.2dB or using 2R2 would give -2.1dB. So those changes would effectively raise the tweeter level by approx +2dB or +1dB. That didn't sound much so I plumped for the +2dB raise and fitted 1R2. It was immediately noticable but after a couple of tracks all I could focus on was the new found treble! There were no nasties with it and it didn't seem to be showing up limitations in the tweeter but it was just too detached and unrealistic sounding. Then went for the 2R2 which should only raise level by 1dB so didn't expect much but it is fantastic! I cannot believe that such a small change has improved the sound to this degree. Still transparent and natural but with the air and presense that was previously lacking. Not just a sound balance thing either as there is now much better soundstaging, presumably as so much directional information comes from the high frequencies. Anyway I realise there won't be millions of these speakers out there but here are the pics,

|

|

#2

|

|||

|

|||

Spec is 89dB/1W with easy 8 ohm load and they are easily driven by the 300B single ended amp. Drivers are 2 x 6" carbon fibre and a 28mm soft dome. Port is unusual and adjustable. The port is a large hole facing down towards the plinth base. You take out those 4 screws, remove the plinth with spikes and change the number of washers between plinth and cab. Mines set on one washer which gives smallest port, basically, the lowest frequency and lowest volume of bass. |

|

#3

|

||||

|

||||

|

I has a similar problem with the spike inserts on my KLS3 speakers, so I made some specials from thick washers and a 6mm thread insert off e-bay.

The thead insert was bronze welded to the washer.

__________________

Philip. Everything in this post is my honest opinion based on what i thought I knew at that very moment in time.

|

|

#4

|

|||

|

|||

|

Neat Philip

Yes I can't understand why they put such weedy inserts in commercial speakers (ok we know - they're tight fisted!). I had just the same with PMC FB1 a while back but Wickes clear 5 minute epoxy sorted them too. Yes I can't understand why they put such weedy inserts in commercial speakers (ok we know - they're tight fisted!). I had just the same with PMC FB1 a while back but Wickes clear 5 minute epoxy sorted them too.What I wanted to be careful about was not pulling the MDF to pieces when getting the loose inserts out, The washer did the trick putting the force close to the edge of the hole (you'll know what I mean anyway being a mechanical sort). |

|

#5

|

||||

|

||||

|

Quote:

I also do wonder whether it is a fact of getting older ourselves that we find we need to increse the level of tweeter to re-dress the balance of sound as we loose HF hearing? Perhaps why you find the tweeter resistor tweak a hit? I'm sure a teenager would find the treble a little harsh with your mod. Last edited by Toppsy; 17th May 2012 at 04:40 PM. Reason: Added text |

|

#6

|

|||

|

|||

|

No I don't think so Colin. I've had many decent quality speakers in this same room for over 20 years and they have all had a slightly brighter balance. I can recognise a dim speaker believe me

Check Noels review linked to in the first post and you'll see he found the same. I'm sure you too have changed tweeter level in your designs to suit system or room. Even going back to my 1977 Pro9TL homebuilds there was provision for changing levels of both mid and treble units by 1.5dB per step. |

|

#7

|

|||

|

|||

|

Hi Richard

Nice Speakers Them Castles  My Mordaunt Short MS812 stand mounts are made from old school good quality Chip Board blue-Tack to my Atacama 24 inch Sand filled Stands and sound great too  And Xover

__________________

The Blues man The Blues man   Turntable Rega 3 custom RB250 with ortofon 2M Blue /other goldring 1042 /WD phono2 /WD CF pre custom converted /WD psu2 /home built JE Labs Single Ended 6SL7/KT66/Speakers Frugal horns Mk1s Other turntables AR EB101/Thorns TD150mk2/Thorns TD160mk2 If you have trouble reading my posts its because I am a dyslexic member |

|

#8

|

|||

|

|||

|

Hi all, here is a mod that you can do to your conways Richard, and other floor standers, take the wooden plinth off and find some very nice person who will make them from solid mild steel, paint them black and put them back

you will be amazed at the sound!!, both top and bottom will be focused much better, well worth the cost you will be amazed at the sound!!, both top and bottom will be focused much better, well worth the cost  . BOB . BOB

|

|

#9

|

|||

|

|||

|

Hi Bob, yes that sounds worth thinking about. I did think at the time I was doing the spikes that if all else fails I could make new plinths as they are just plates 9 x 12 x 1 inches. Rough calc says they'd weigh 12Kg in steel! Do they have to be black for this to work though

Marble or granite might be an option too as quite a few kitchen places cut and polish the edges now. The spike inserts could be glued in again but I'm not sure what drills I'd need for them and the cabinet bolt holes? Marble or granite might be an option too as quite a few kitchen places cut and polish the edges now. The spike inserts could be glued in again but I'm not sure what drills I'd need for them and the cabinet bolt holes?

|

|

#10

|

|||

|

|||

|

Richard, it is the weight that holds the cab. solid, I made some for a pair of transmition lines, god knows the weight but they were 12" x 10" x 3". If you ever need imfo on drill and tap size, just shout, metric is easy, just deduct the pitch from the tap size, and that is the drill size, for example, 8mm tap with 1.25 pitch = 6.75 drill, 6.80 will do. BOB

|